Best Deck Waterproofing in Orange County, CA

Proper waterproofing is essential for maintaining a beautiful, durable deck in Orange County, CA. The region’s sun, rain, and moisture fluctuations make waterproofing necessary to prevent damage, ensure safety, and extend the life of your deck. Hiring a reputable deck waterproofing contractor is the best way to protect your investment.

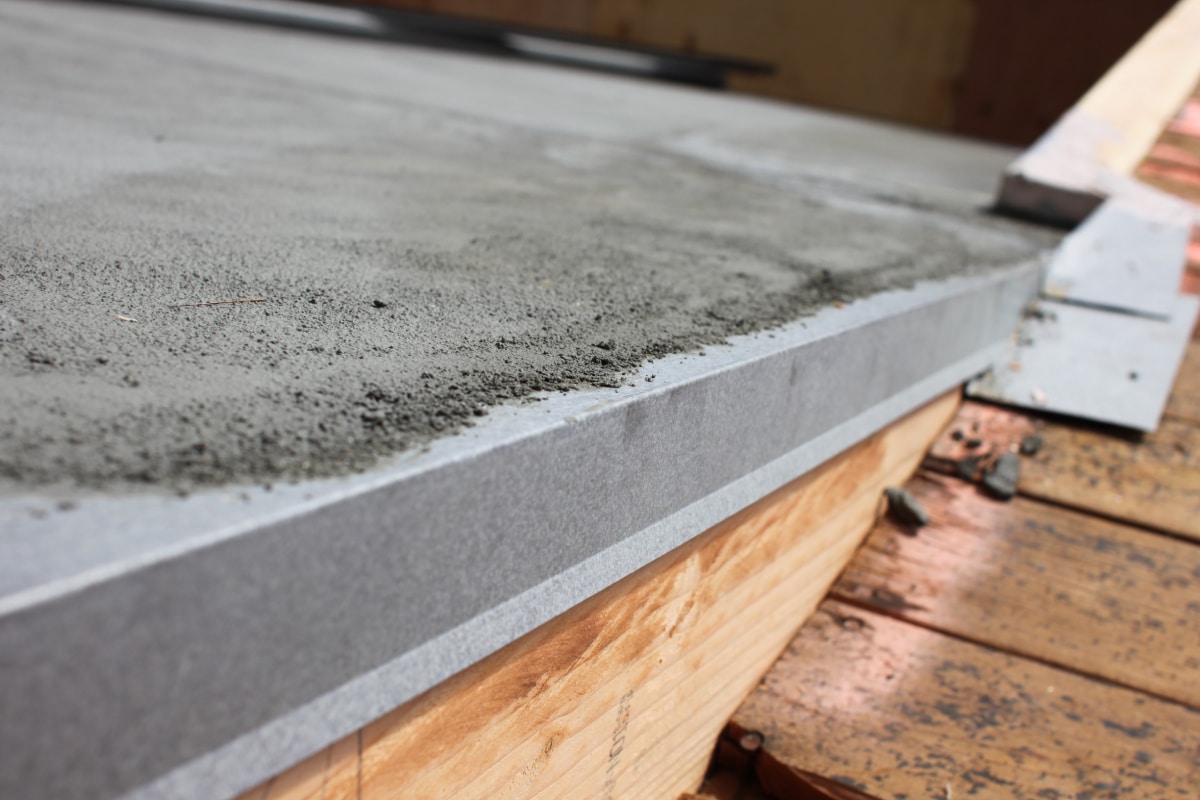

Deck Waterproofing

CALL TODAY FOR A FREE ONSITE ESTIMATE! (949) 289-9853

Find the Best Deck Waterproofing Contractor in Orange County, CA

Here’s a comprehensive guide on how to find the best deck waterproofing waterproofing specialist, with Prestige Deck Coating highlighted as a top choice for reliable and professional services in Orange County.

Here’s a comprehensive guide on how to find the best deck waterproofing waterproofing specialist, with Prestige Deck Coating highlighted as a top choice for reliable and professional services in Orange County.

1) Understand the Importance of Deck Waterproofing

A well-waterproofed deck is more durable, safer, and visually appealing. Without proper waterproofing, decks can suffer from issues such as:

- Moisture Damage: Unprotected decks are prone to moisture absorption, which leads to wood rot, mold, and mildew and weakens the deck’s structural integrity.

- UV Damage: Constant exposure to sunlight can cause fading, warping, and cracking.

- Safety Hazards: Wet, slippery decks increase the risk of accidents while decaying wood can lead to structural failure.

To avoid these issues, selecting a contractor with extensive knowledge of the latest waterproofing techniques and materials is crucial.

2) Identify Essential Qualities of a Great Deck Waterproofing Contractor

When choosing a contractor for deck waterproofing, consider the following qualities:

- Experience and Expertise: Look for companies with years of experience in deck waterproofing.

- Licensing and Insurance: The contractor should be licensed, bonded, and insured to protect you from liabilities.

- Quality Materials: A reliable contractor should use premium waterproofing materials that provide lasting protection against the elements.

- Positive Reputation: Look for contractors with excellent reviews and a strong reputation in the community.

3) Steps to Find the Right Contractor

3) Steps to Find the Right Contractor

Finding the best deck waterproofing specialists requires careful consideration. Here’s a step-by-step approach to simplify the process:

Step 1: Do Your Research

Start by compiling a list of contractors specializing in deck waterproofing in Orange County. Research each company, checking for details like their services, materials used, and areas served.

Step 2: Check Credentials

Verify the contractor’s license and insurance status. A licensed contractor has met state standards, while insurance protects against accidental damage during the project.

Step 3: Review Portfolios and Testimonials

Look for reviews on platforms like Google, Yelp, or the contractor’s website. Also, check if the contractor has a portfolio showcasing completed waterproofing projects.

Step 4: Ask About Waterproofing Techniques

A top-notch contractor should be knowledgeable about various waterproofing methods and be able to explain which method best suits your deck. Some standard techniques include membrane waterproofing, deck coating, and specialized sealants.

Step 5: Compare Quotes

Request detailed quotes from multiple contractors. A trustworthy contractor will provide a transparent quote that breaks down materials and labor costs.

4) Why Choose Prestige Deck Coating?

Prestige Deck Coating stands out as one of Southern California’s best deck waterproofing contractors. Here’s what makes them a top choice for homeowners seeking exceptional waterproofing services:

- Years of Expertise: With decades of experience, Prestige Deck Coating brings deep knowledge and skill to every project. Our team has seen it all and knows how to handle unique pool deck waterproofing challenges.

- Quality Materials and Techniques: Prestige Deck Coating uses industry-leading materials, ensuring durability and long-term protection. We are experts in applying various waterproofing coatings and systems.

- Customer-Centric Approach: Prestige Deck Coating is known for its commitment to customer satisfaction. It offers excellent communication, personalized service, and a focus on meeting client expectations.

- Positive Reputation: With numerous positive testimonials and a strong reputation in Orange County, Prestige Deck Coating has become a trusted name in the deck waterproofing industry.

5) Top Questions to Ask Your Deck Waterproofing Contractor

When you meet with prospective contractors, asking the right questions can help determine their suitability for your pool deck projects. Here are some essential questions to consider:

- What waterproofing methods do you use, and why?

- Do you have references or a portfolio of previous projects?

- What materials do you use, and are they environmentally friendly?

- How long will the waterproofing last before maintenance is required?

- What is the estimated timeline for completing the project?

- Do you offer any warranties or guarantees on your work?

A reputable contractor, like Prestige Deck Coating, will provide thorough answers and help you understand the waterproofing process in detail.

6) Understanding Different Deck Waterproofing Techniques

There are several popular deck waterproofing methods, and a professional contractor should be well-versed in all of them:

- Polyurethane Coating: Polyurethane coatings are durable and protect from UV rays and moisture.

- Epoxy Coating: Epoxy coatings are highly resilient, making them famous for decks that endure heavy foot traffic.

- Acrylic Coating: Acrylic coatings are water-based, environmentally friendly, and provide a beautiful finish, ideal for outdoor aesthetics.

- Rubberized Coatings: These are highly flexible and weather-resistant, suitable for regions with fluctuating temperatures.

7) Factors That Impact Waterproofing Costs

The cost of deck waterproofing can vary based on several factors:

- Deck Size: Larger decks require more materials and time, increasing the project cost.

- Condition of the Deck: A deck with pre-existing damage or rot may need repairs before waterproofing.

- Type of Coating: Premium waterproofing materials like epoxy or polyurethane are more costly but offer extended protection.

- Complexity of the Project: Multi-level decks, stairs, or unique designs may increase the labor and materials required.

Prestige Deck Coating provides a detailed breakdown of costs for a transparent estimate, ensuring no hidden fees or surprises.

8) Tips for Maintaining Your Waterproofed Deck

After your deck is professionally waterproofed, maintaining it is essential to ensure longevity. Here are a few maintenance tips:

- Clean Regularly: Sweep off debris, dirt, and leaves to prevent mold growth.

- Inspect for Cracks: Look for any signs of cracking or peeling and address them promptly.

- Reapply Waterproofing When Necessary: Depending on exposure and wear, some coatings may require reapplication every few years.

- Protect from Heavy Impact: Do not drop heavy items on the deck, as they can damage the waterproofing layer.

Your contractor can provide specific maintenance advice based on the waterproofing material used.

Your contractor can provide specific maintenance advice based on the waterproofing material used.

9) Benefits of Hiring a Professional Deck Waterproofing Contractor

Attempting to waterproof a deck yourself can be challenging and may lead to improper application or material choice. Here’s why hiring a professional contractor is a wise decision:

- Expertise: Professional contractors have years of training, ensuring effective waterproofing to withstand the elements.

- Quality Materials: Contractors have access to high-grade, industry-approved materials that are not readily available to consumers.

- Time and Cost Efficiency: Contractors complete the job efficiently, using professional tools and techniques, saving you time and potential repair costs.

- Guaranteed Results: Most reputable contractors offer warranties on their work, giving you peace of mind.

Prestige Deck Coating exemplifies these benefits, offering a blend of expertise, top-quality materials, and reliable customer service.

10) Conclusion: Why Prestige Deck Coating is a Top Choice

In Orange County, deck waterproofing is crucial for preserving outdoor spaces’ structural integrity, safety, and beauty. Choosing the right contractor can make all the difference, and Prestige Deck Coating is a leading choice for homeowners who prioritize quality, reliability, and professionalism. With decades of experience, superior materials, and a client-focused approach, they bring top-notch waterproofing solutions to your deck, ensuring it remains in excellent condition for years.

Ready to protect your deck and enhance your outdoor living space? Contact Prestige Deck Coating, one of the best deck waterproofing contractors in Orange County, CA, for a consultation today.

Ready to protect your deck and enhance your outdoor living space? Contact Prestige Deck Coating, one of the best deck waterproofing contractors in Orange County, CA, for a consultation today.

Why Choose Prestige Deck Coating?

We are one the the best deck waterproofing contractor in the South Orange County Area.

We have professional service and knowledgeable staff, which has helped our company to grow into one of the best in the industry. Our team is made up of only the highest-quality installers.

We provide Pool Deck Resurfacing services in cities of Aliso Viejo, Anaheim, Anaheim Hills, Balboa Island, Bell Canyon, Brea, Buena Park, Capistrano Beach, Corona Del Mar, Costa Mesa, Coto de Caza, Cypress, Dana Point, Dove Canyon, El Toro, Foothill Ranch, Fountain Valley, Fullerton, Garden Grove, Huntington Beach, Irvine, La Habra, La Palma, Ladera Ranch, Laguna Beach, Laguna Hills, Laguna Niguel, Laguna Woods, Lake Forest, Las Flores, Los Alamitos, Midway City, Mission Viejo, Modjeska Canyon, Monarch Beach, Newport Beach, Newport Coast, Orange, Placentia, Rancho Santa Margarita, San Clemente, San Juan Capistrano, Santa Ana, Seal Beach, Silverado, Stanton, Sunset Beach, Trabuco Canyon, Tustin, Villa Park, Westminster, and Yorba Linda in Orange County, CA.